How to Fix DTC P003A in Duramax Trucks

A diesel truck – especially one with a Duramax engine – is a big investment, and you want to take care of it. So, if you get a scan and it comes back with a trouble code, it pays to know what’s going on under the hood.

One of the most common DTCs (diagnostic trouble codes) for Duramax trucks is P003A. Here’s what you need to know if you encounter it, and the steps you should follow to fix it What is DTC P003A?

When your mechanic or code reader has scanned your truck’s engine computer, DTC P003A is one of the possible errors that can come back. Obviously, that doesn’t mean much to someone unfamiliar with the scanner!

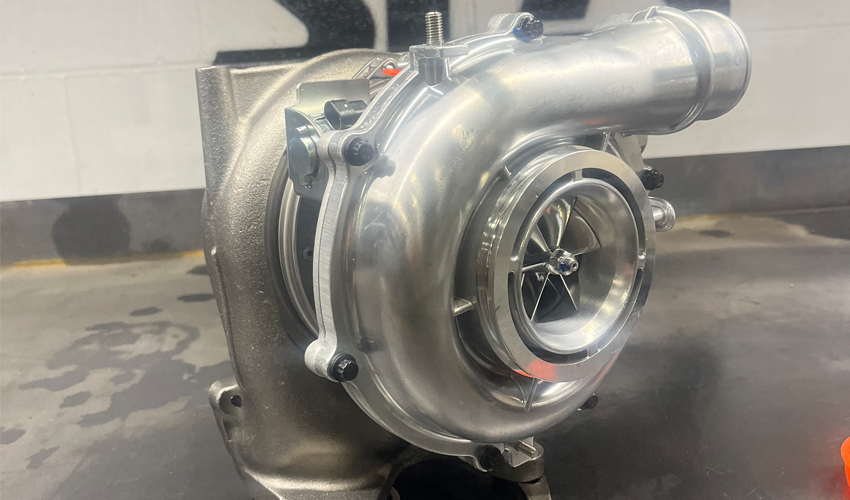

The technical definition of this DTC is that “the turbo charger/super charger boost control A position has exceeded the learning limit.” In plainer terms, this means that the variable geometry turbo (VGT) turbine vanes cannot move from 0% (open) to 100% (closed) fast enough. What Are Turbine Vanes?

So, now you’re likely asking: what are turbine vanes?

Well, these are what enable the turbo to change its efficiencies throughout the engines RPM range. At a low RPM, they allow it to act much smaller and function as a small, quick-spooling turbo. At a high RPM, they allow it to act much larger and provide more top end power. The vanes are what regulate air through the exhaust side(or better known as the turbine) of the turbo, where it can start spinning the turbine. At lower RPMs, the vanes will close up to 100%, letting only small amounts of air through – but because of the small opening, the air pressure rises and causes it to move faster. This starts spinning the turbine. Then, as engine RPM and power increase, the vanes open up more and more from that initial 100% closed position. They can go all the way to a 0% closed (in other words, wide open) position, depending on how much boost pressure your truck requires. Though they were originally designed for emissions purposes, the after-market has embraced this design to maximize the narrow power band that a diesel engine operates in. How Turbo Vanes Function

Every time your engine starts up, the engine control module (ECM) performs a process known as a turbo vane position learn. Essentially, this means the computer tells the turbo to close the vanes to a point between 0% and 100%, and periodically throughout your drive, it will repeat the process.

The computer uses engine oil pressure to cycle the vanes from 0-100%. This pressure pushes a plunger, which moves the unison ring and, in turn, cycles the vanes through their whole range from closed to open. In a P003A code, the problem lies with the unison ring: it seizes up and can no longer turn its full motion. This is generally caused by rust on the turbo cartridge, which stops the ring and causes the turbine vanes to “stick” Why Can Trucks Drive With a P003A Code?

In everyday driving, the vanes function almost entirely between the 20%-90% range. When the ECM does a periodic vane position learn, it makes them open from 0% to 100%, and these outer limits are where the vanes become stuck or slow to respond.

After-market tuning can exaggerate a sticky vane issue, because when trying to exhaust brake (100%) or “rumble idle” (0-20%), the turbo is being sent beyond its “worn-in” range. The coolant temperature and length of idle will also affect the performance, because when the engine is cold, oil pressure is high and more force will be put onto the plunger and unison ring. This often forces the vanes through the stuck positions. However, as engine oil temperature increases, oil pressure drops and it no longer has enough pressure to work through the rusted portions

The Most Common Misdiagnosis of DTC P003A

The main mistake involved in this DTC is assuming that the vane position sensor is faulty. As we know, it’s almost always the unison ring getting stuck, which prevents the sensor from seeing what is happening. The sensor reads correctly, but the ring is physically stuck and cannot push the vanes to the proper places that the ECM is asking for.

These sensors rarely fail and are easy to test when removed from the turbo, which means it’s simple to ensure they are not the problem. Beyond that, the best way to diagnose a sticking unison ring is with a scan tool that can command a vane position. To do this procedure, you should cycle the vanes from 0% to 100% while the engine is hot. If the ring is working properly, this vane sweep should be completed within 1 second. If it takes more time than that, or there is a slow response on either end of the position, it’s likely that the unison ring is getting caught up on a rusted turbo cartridge How To Fix DTC P003A

For a temporary fix, it’s possible to remove the turbo, split it apart, and remove the rust on the cartridge where it meets the unison ring. This may give you a few more years of service, but remember – if it rusted once, it is basically guaranteed to rust again. The permanent fix is to replace the turbo with a new unit with additional “pins” installed in the cartridge. These pins help clean the unison ring and promote a longer life of the components

Here at Schultz Diesel Sports, all new turbos have these scrapers installed to ensure you get many years of great service. If you’re getting the DTC P003A reading on your Duramax truck, reach out and let us know – we’ll have it running like new in no time

14 Comments

Ian Farrell

1/16/2023 11:05:07 am

Sounds exactly like my problem this last summer! I enjoyed the read thanks!

Reply

Armando Gonzalez

5/24/2023 05:22:32 am

Great information,a have a year working on Diesel trucks tanks guys 👦

Reply

Brett Baird

5/24/2023 07:16:01 pm

Hi, last night was driving back from a softball game going maybe 60 mph when I got a check engine light. Take it to oreily’s today and get back a p003a code. Started truck for 4th time tonight engine was warm and code goes away… any help is appreciated!

Reply

8/9/2023 04:53:07 pm

just replace the old turbo for a new one the old one was acting up anyway the new one from Orreilys after a week of been installed I got a code p003A so my question is would a new turbo can be damaged or get damaged this fast never had a this problem with the old one thank you in advance.

Reply

Paul W

1/16/2024 06:46:38 am

Did you ever find out what happened to your new turbo? Or why it threw the code?

Reply

RYAN

3/7/2024 09:07:17 am

SAME THING WITH NEW TURBO FROM O'REILEYS. DID YOU FIND A FIX?

Reply

1/14/2024 09:14:13 pm

What diagnostic procedures should be followed to rectify DTC P003A issues in Duramax trucks? Greeting : <a href="https://sas.telkomuniversity.ac.id/en/">Telkom University</a>

Reply

Barry

2/20/2024 03:58:45 pm

code P003A on my LBZ

Reply

2/25/2024 08:14:00 pm

Nice for information

Reply

Bob Brown

3/2/2024 05:32:13 am

Is possible to install a better ring in a turbo on a 1500 3.0l lm2 engine.

Reply

Precious

6/29/2024 01:33:04 am

P003a means the actuator needs calibrating to the turbo and ecm. Usually the truck drives fine, but it can have low boost or no exhaust brake.

Reply

jore r.baxter

7/4/2024 07:41:45 pm

isthere anyway to lube this ring a nd help without pullig the turbo

Reply

Leave a Reply. |

Frequency

Come back each month to see a new original article we have written! Categories |

HoursM-T: 7am - 6pm

|

Telephone |

|

RSS Feed

RSS Feed